The space technology market is in a state of dynamic change. While space tech companies are often associated with bold scientific advances, much of the fundamental technology involved in launching payloads into orbit has remained largely unchanged. However, this is beginning to change. Cutting-edge space tech companies are harnessing technologies like 3D printing to fundamentally reimagine rocket propulsion and open new possibilities in space access.

Firehawk Aerospace’s story starts in 2020 when the business raised seed financing of $2.5 million to commercialize patents related to the 3D-printing of fuel grains. The growing venture quickly started serving the defense industry, partnering with Raytheon Missiles and Defense (who also invested in the company). Space Impulse spoke to Will Edwards (CEO) and Dr. Justin Karl (Chief Engineer) of Firehawk Aerospace in an exclusive interview.

Karl – the rocket scientist – had some history in exploring the potential of modernizing hybrid rocket propulsion, an engine type that uses a solid propellant with a liquid oxidizer. Seeking to leverage additive manufacturing to solve some of the inherent issues, he actually worked with one of Firehawk’s founders long ago and was excited to hear about the progress. He joined the business last year to lead its research, development and testing operations.

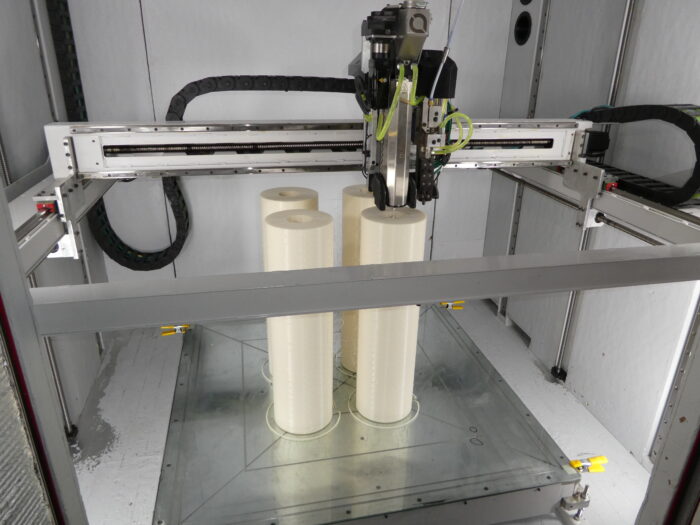

3D Printing Rocket Fuel

All space companies need storable “delta V” (changing relative velocity- the end result of a rocket firing) but liquid propellants boil off and solid propellants are one and done. Hybrid systems offer a simple and reliable solution. Their 3D printed rocket fuel has become the company’s secret weapon, capable of increasing efficiency and reducing supply chain constraints. The thermoplastic-based fuel can be stored indefinitely without moisture affecting it.

“Our 3D printing is really just fancy plastics that have roughly the same chemical makeup as the fuels that have been used for decades and decades, but they perform better because you can tailor those surfaces perfectly. …[Using] layer by layer deposition, there’s no chance of getting gaps or bubbles or any deficiencies,” says Karl.

Growing the Business

Firehawk believes that the key to their success lies equally in their technical breakthrough as well as their disruption of the supply chain. By producing fuel quickly and cheaply with common materials, Firehawk is strategically positioned to have a major impact on rocket production and space travel.

The company’s goal is to build partnerships, gain contracts, and build a strong team dedicated to their cutting-edge approach to rocket systems. Investors appear eager to back their vision, with the business receiving another circa $20 million in their Series B in September 2022.

Edwards highlights the importance of partnerships:

“We have some of the biggest companies in the world coming into our facilities, that we’re [then] working with and securing large contracts through our partnership approach.”

Karl notes that there has been a remarkable transformation in the industry where businesses need to demonstrate real impact much faster.

“There used to be a time where you could build an entire company around promises and there was a 10-year window before you could even consider booking a launch” he says. “You could really dance around the problem and continue to raise or continue to pull contracts without performing.”

Defense and Space

We closed the interview by asking what the most common misconception is in the space industry. Edwards was quick to answer:

“That every space company is a defense company.”

Every piece of space technology is essentially a piece of defense technology that has matured and evolved into a reliable space infrastructure item. Both sectors, Edwards affirmed, are crucial for innovation. He stressed that this technology dual-use is integral to attracting investors, as futuristic space ideas often lack near-term revenue opportunities. By demonstrating an understanding of the technology development path, companies can reassure investors about their maturity and revenue potential. Once the technology transforms from a strategic asset exclusive to a country into a globally accessible one, it is considered a mature piece of tech and therefore having a grasp of this process is a sign of a company’s maturity.

As Firehawk Aerospace continues to disrupt the industry with innovative technology, strategic partnerships and commitment to progress while also pushing the boundaries of what is possible with 3D printed rocket fuel, the pioneering space company is well positioned for future success on the space market.

Featured image: Credit: Firehawk Aerospace

Share this article: