Insider Brief:

- Redwire Space NV has been awarded a €14 million (USD 15.3 million) contract under a program of and funded by the Exploration Programme of the European Space Agency to design, develop, and qualify the 3D-BioSystem Facility.

- The 3D-BioSystem Facility will leverage the latest 3D bioprinting technologies to provide a modular, powerful, and unique system to sustain a large number of experiments.

- The 3D-BioSystem Facility could help better understand cell to cell interactions in thick tissue, creating organoids for drug efficacy and toxicity testing, laying the groundwork for printing vascularized tissue, and printing transplantable organ patches for tissue therapy.

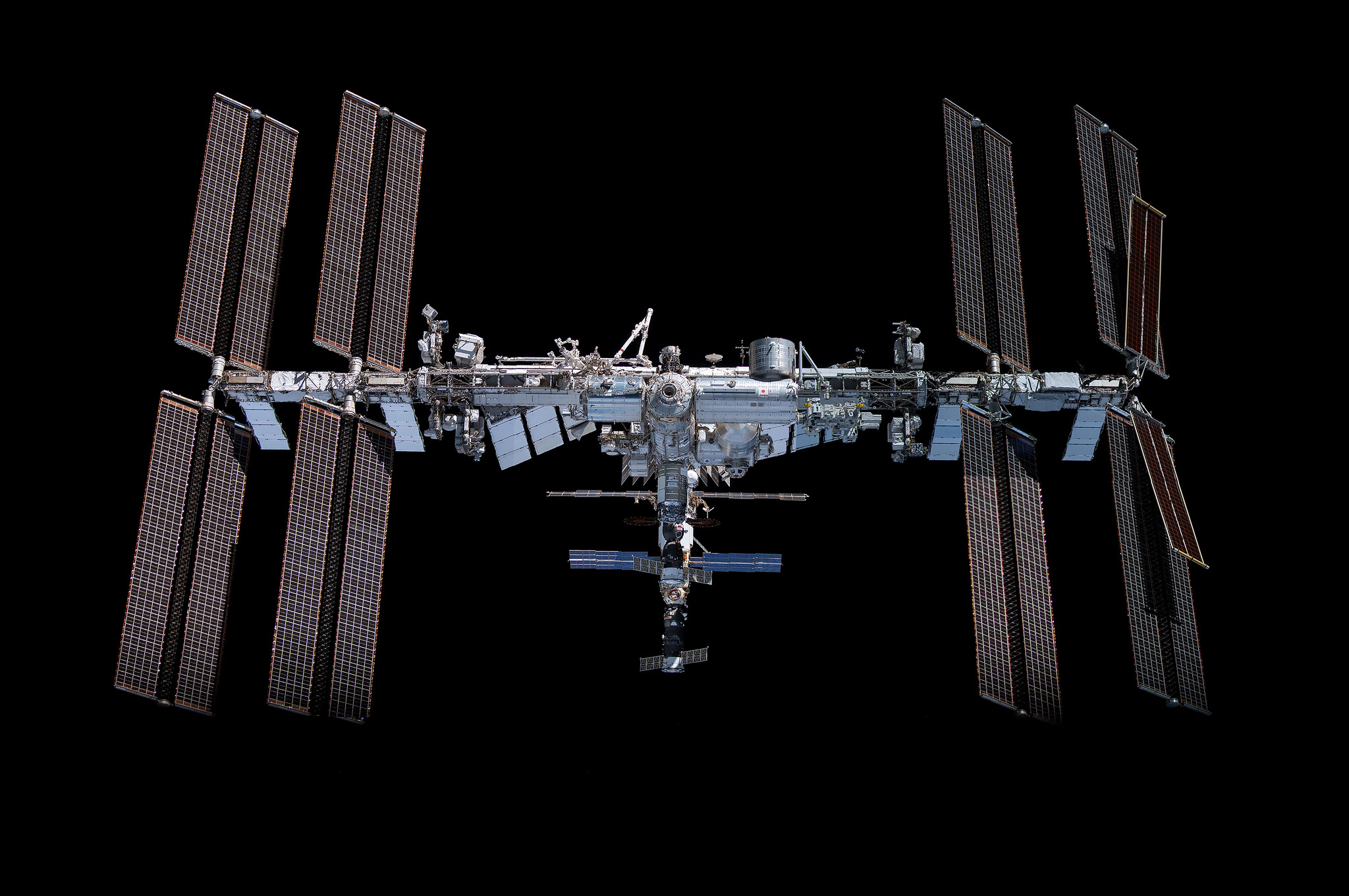

PRESS RELEASE — Jacksonville, Florida / May 9, 2023 — Redwire Corporation (NYSE: RDW), a leader in space infrastructure for the next generation space economy, announced today that its wholly owned subsidiary, Redwire Space NV, has been awarded a 14 million euro contract under a program of and funded by the Exploration Programme of the European Space Agency to design, develop, and qualify the 3D-BioSystem Facility. Being developed by Redwire Space NV, a Belgian legal entity, the 3D-BioSystem Facility will leverage the latest 3D bioprinting technologies to provide a modular, powerful, and unique system to sustain a large number of experiments. Expanding Redwire’s legacy of in-space manufacturing and bioprinting on the International Space Station (ISS) for exploration and improving life on Earth, the 3D-BioSystem Facility will be a “one-stop shop” for tissue engineering and regenerative medicine.

“We are proud to be developing the 3D-BioSystem to advance critical microgravity bioprinting capabilities,” said Erik Masure, Redwire Space NV Managing Director. “The ability to bioprint cell constructs will be critical for long-duration spaceflight expeditions to the Moon, Mars, and beyond and for sustainable planetary settlements.”

The system will include a 3D bioprinter, 3D cell culture units, and an incubator. The 3D-BioSystem will be able to produce samples in orbit, which can then be further processed there or be returned to ground.

Redwire Space NV’s 3D-BioSystem Facility could be an important tool for better understanding cell to cell interactions in thick tissue, creating organoids for drug efficacy and toxicity testing, laying the groundwork for printing vascularized tissue, and, in the future, printing transplantable organ patches for tissue therapy. The system will also help ensure European technological non-dependence and competitiveness, which is crucial to securing space benefits for Earth and expanding the global space economy.

Redwire is a leader in microgravity bioprinting. Redwire’s BioFabrication Facility (BFF), a flight dedicated 3D bioprinter, is currently operating on the ISS. BFF is being used for the BFF-Meniscus-2 investigation, which will use BFF to print human knee meniscus. The investigation, a collaboration between Redwire and the Uniformed Services University of the Health Sciences Center for Biotechnology, is exploring how space bioprinting could help treat meniscal injuries, one of the most common orthopedic injuries affecting U.S. military service members. Like BFF, the 3D-BioSystem Facility has the potential to advance biomedical research to improve life on Earth.

Redwire’s large and diverse catalog of equipment and services is being used by government, institutional and industrial customers for conducting research in microgravity. Redwire’s on-orbit capabilities are advancing biomedical capabilities, advanced materials manufacturing, and plant biology, all in an effort to accelerate more scientific discovery and deliver more beneficial products to Earth.

Contact Information:

Media Contact:

Emily Devine

[email protected]

305-632-9137

Media Contact (Redwire Europe):

Marta Lebron

[email protected]

+32 3 250 14 50

OR

Investors:

[email protected]

904-425-1431

SOURCE: Redwire Space

Featured image: Credit: Redwire Space

If you found this article to be informative, you can explore more current space industry news, exclusives, interviews, and podcasts.

Share this article: